PET Sheet Extrusion Line,PET Transparent Sheet Production Machine

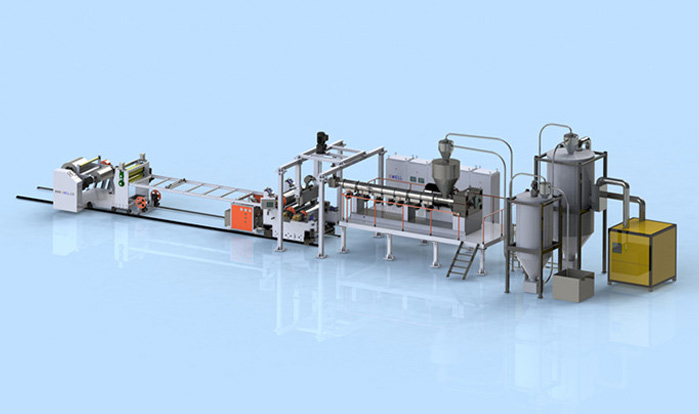

Gwell PET sheet extrusion production line is company's strategic continuous improvement model. As to this equipment, company adopts the special sales model to ensure the first market share, the lowest price for the same parameter configuration, and the first echelon of PET industry for continuous technology upgrading. The raw materials can be APET, PETG, RPET, etc.

1. Introduction of PET sheet machine

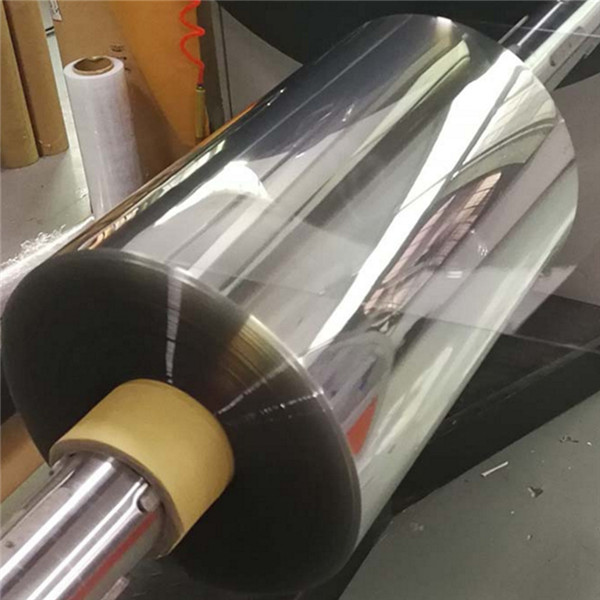

(1)Single screw production line for PET sheet: single screw extrusion production line for APET, PETG and CPET sheet is the most mature project with the most stable production at present. Generally, single extruder production line or twin-extruder production line is adopted and Gwell uses the latest technology to increase the general efficiency by 30%.The transparency of PET sheet can reach optical level.

However, this model has very high requirements for raw material processing, and the PET raw material needs to be crystallized and dried. This can ensure that the produced PET sheet has no crystal points, whiteness, and poor transparency.

The main features of PET high transparency sheet: impact resistance, excellent processability, good chemical resistance, and good insulation.

The main applications of PET high transparency sheet: food packaging and gift packing

(2) PET high transparent sheet single-screw exhaust production equipment: APET, PETG, CPET sheet single-screw exhaust extrusion production line is improved from the PET high-transparent sheet production equipment, which increases the exhaust function, Make the material in the screw barrel easier to remove the gas and excess water in the material. This equipment is not very strict on raw material processing. It only needs to crystallize the raw materials without drying. The quality of the products produced is also very good.

Type of machine | GWS90 single screw | GWS120 single screw | GWS150 single screw |

Width of product | 600mm - 800mm | 800mm - 1200mm | 1000mm - 1500mm |

Thickness of product | 0.15mm - 2mm | 0.15mm - 2mm | 0.15mm - 2mm |

Output | 150KG/H - 200KG/H | 300KG/H - 400KG/H | 400KG/H - 500KG/H |

(3) PET sheet twin-screw exhaust production line: APET, PETG, CPET sheet twin-screw exhaust extrusion production line is improved from PET sheet single-screw production equipment. The raw material processing non-crystallization, non-drying exhaust type PET sheet unit of this production equipment has the advantages of low energy consumption and high efficiency. This model is a continuous improvement and upgrade product of Gwell. It has made significant improvements to the core vacuum system. The technology upgrades from the original Roots-water ring pump set to the Roots-rotary vane pump set, which can make the vacuum reach ≤10Pa. At the same time, the PET special alloy steel thin-walled roller set is used to greatly improve the cooling efficiency, thereby increase output, improve product toughness and transparency. The operating system independently written by Gwell ensures the humanization and easy operation of the equipment.

(4) PET three-layer sheet production line or GAG sheet production line: APET, PETG, CPET three-layer sheet extrusion production line is improved from PET sheet production equipment. According to different types of extruders, there are different raw material processing methods. This machine uses two or more extruders. Either a single-screw extruder or a twin-screw extruder can be used to produce three-layer PET sheets.

GAG sheet is the most commonly used PET three-layer sheet, which is composed of PETG+APET+PETG through an extruder, distributor and die. It is widely used in furniture and decoration materials.

Type of machine | GWP75 Twin screw+GWS65 Single screw | GWP85 Twin screw+GWP52 twin screw | GWP95 Twin screw+GWP65Twin screw |

Width of product | 800mm - 1000mm | 800mm - 1200mm | 1000mm - 1500mm |

Thickness of product | 0.15mm - 2mm | 0.15mm - 2mm | 0.15mm - 2mm |

Output | 300KG/H - 450KG/H | 500KG/H - 600KG/H | 800KG/H - 900KG/H |