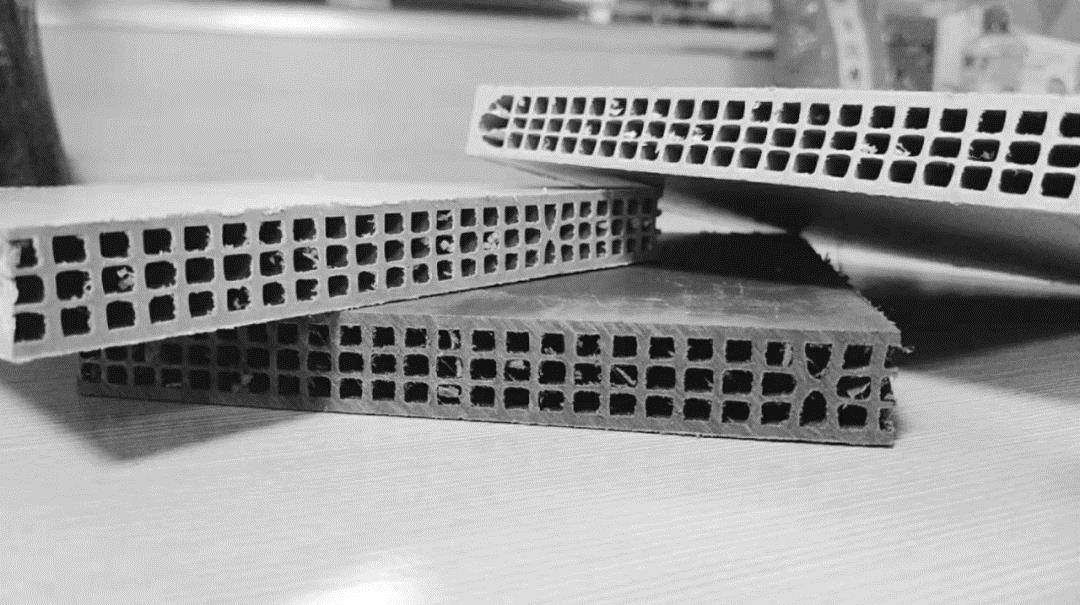

Plastic formwork is a composite material extruded through a high temperature of 200 ° C. It is an energy-saving green product and an important component of building formwork. It has a high number of turnovers (more than 30-50 times), a large temperature adaptability range, strong specification adaptability, and convenient construction, which can meet the requirements of various rectangular, cuboid, L-shaped, and U-shaped building molds. It has the functions of flame retardant, anticorrosion, water resistance and chemical corrosion resistance, has good mechanical properties and electrical insulation properties, and can be used for a long time (more than 8 years). It also has the characteristics of good water surface effect, light weight and high strength. It can also be recycled and reused 100%, which is in line with national environmental protection and circular economy policies.

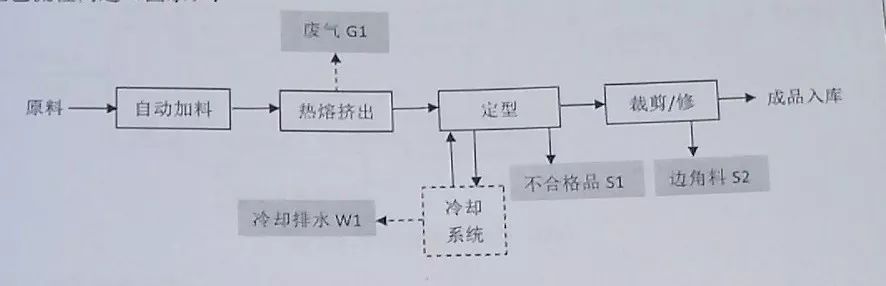

Second, PP hollow building template production process

The raw materials (pp granules and fragments) are continuously sent to the PP hollow template extruder (integrated equipment) through the hopper, and the materials are heated to 160 ~ 170 ° C (automatic temperature controlled electric heating) under the automatic stirring state to soften them; This process will produce a small amount of organic waste gas G1 (based on total non-methane hydrocarbons) = the softened material is extruded in a PP hollow template extruder and conveyed to the cooling system via a conveyor belt for cooling (indirect cooling, cooling water circulation, periodic A certain amount of cooling and drainage w1) is discharged to complete the shaping. After cutting, trimming and finishing, the above processes of storage of finished products will generate a certain amount of defective products 51 and scraps S2, which will be comprehensively used after being crushed by a crusher.